The UK railway standard GMRT2100 provides minimum performance requirements for structural integrity and human injury when impacting a table in a crash scenario. Using the fully validated Humanetics anthropomorphic test devices (ATD’s) Design and Analysis Ltd can predict the structural performance of the table and demonstrate design acceptability without the need for expensive physical testing.

If conducted in advance of physical testing this analysis can be implemented at the design stage before any manufacturing tooling is made, ensuring a right first time approach and limiting exposure to expensive design change and most importantly reducing the risk of project delays.

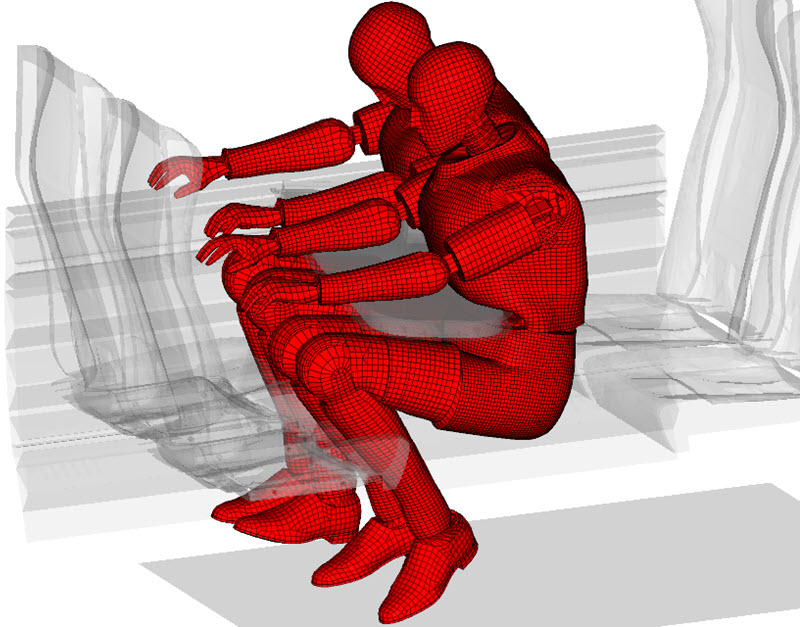

The video below shows 2 x 95th Percentile Hybrid III Humanetics ATD’s impacting a table. Note the deformation of the table seen under impact. The table design has to be able to withstand this impact without structural failure whilst not deforming so much that the survival space of the opposing seated occupants is compromised. There is often a fine balance between passing this requirement and not being too rigid to compromise the human injury requirement shown in the next video.

The video below shows 1 x 50th Percentile Thor Humanetics ATD impacting a table. In this case a single ATD located nearest the bodyside is a worst case due to the table being stiffer near the bodyside attachment. The Thor ATD is used for the advanced abdomen sensors which are critical for table impact. The Hybrid III RS version of the standard Hybrid III, uses the abdomen from the Thor. The accelerations and deflections from the sensors integrated within the ATD allow post-process calculation of injury levels for comparison against the injury level limits defined within the standard.